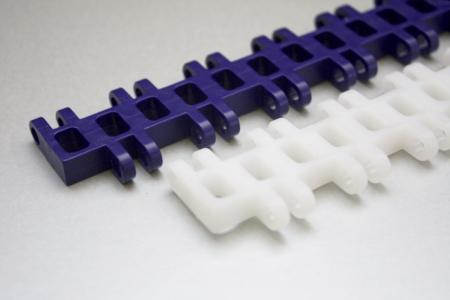

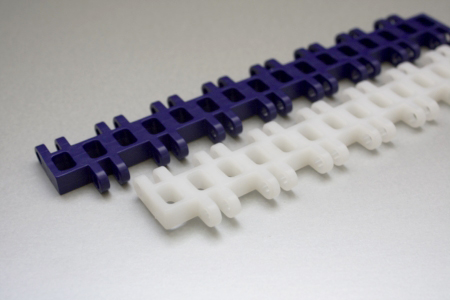

P.25-400

Belt Surface: Open belt with a smooth surface

Open Area: 29%, 6 x 10 mm

Strength: Medium transportation

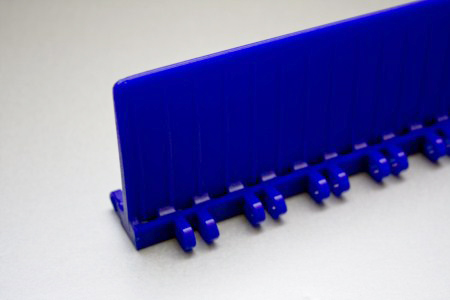

Materials/Color: PE/Nat, PP/White or Gray and POM/Blue

Width Interval: 25 mm

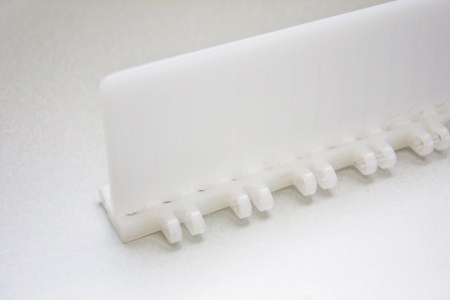

Accessories: Flights, side guards and friction top

Applications: Seafood, red meat, vegetables, bakery and the food industry in general; even cooling/freezing and washing.

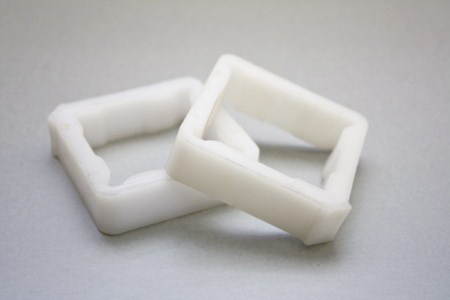

Related Accessories

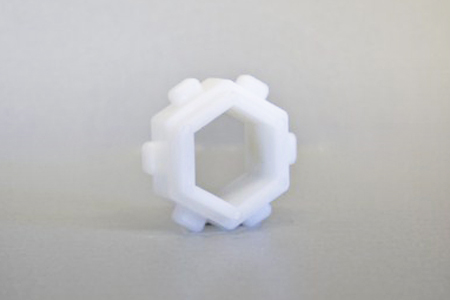

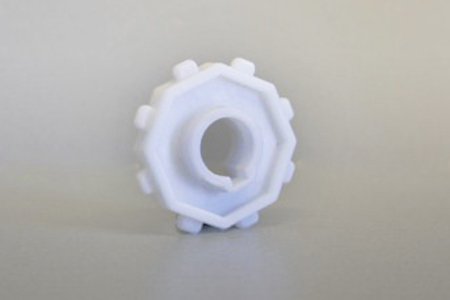

Related Sprockets

Standard Belt Material Properties

1) Polyethylene (PE) is the most lightweight and flexible of the plastic modular belt materials. PE belts are characterized by good chemical resistance, water buoyancy and high impact strength. PE will also be ideal for applications that require a flexible belt material with superior impact strength. A broad temperature range of -100ºF (-73ºC) to 150ºF (66ºC) makes this material an ideal choice for seafood and dairy processing applications or any other cold area applications.

2) Polypropylene (PP) is a harder material with an excellent pulling force. PP also has an excellent chemical resistance towards hostile cleaning chemicals and therefore is ideal for applications that require high chemical resistance. PP is the belt of choice for higher temperature applications with a temperature range of 41ºF (5ºC) to 212ºF (100ºC). PP belts are perfect for bakery, meat, and poultry processing applications where high temperature can be a factor.

3) Polyacetal (POM) is the strongest, heaviest and most tolerable of the three standard belting materials. It has a vast pulling force and a hard surface, which leads to reduced friction for the product. It should be used with caution in installations that use cleaning agents that contain acid and/or chlorine. POM is also sensitive to force due to its low impact strength. This belt is well suited to heavier food processing, bottling and canning industry. The acceptable temperature range for a POM belt is from -45ºF (-43ºC) to 203ºF (95ºC).

Note: Belts are manufactured from CFIA/USDA/FSIS approved materials.